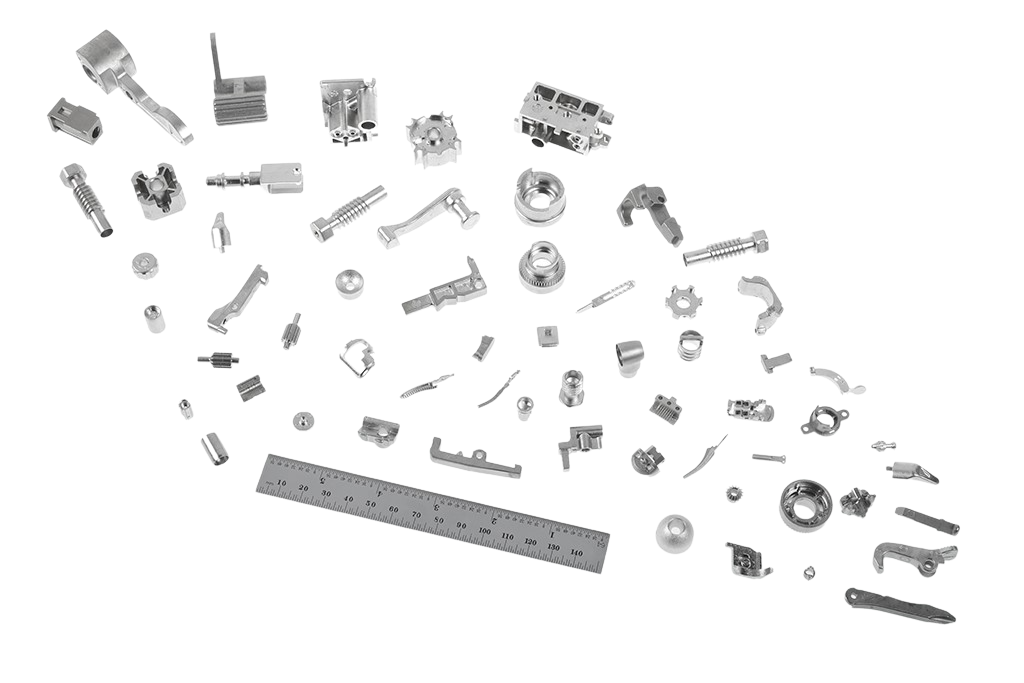

Create Precision Metal Parts with Multiple Benefits

Metal injection molding (MIM) efficiently produces complex, precision parts from various materials, offering up to 50 percent cost savings over 5-axis CNC machining and faster, high-resolution finishes than investment casting. Known for creating intricate, strong parts with excellent surface finish, MIM excels in high-volume manufacturing, making it a popular choice for industries such as medical, automotive, industrial, defense and electronics.

MIM Advantages

MIM is an innovative yet uniquely cost-effective injection molding method that creates precision-shaped metal parts—making it especially advantageous in situations requiring multiple secondary operations or multi-piece assembly. Because MIM accommodates numerous materials (see table below), product developers can create small custom parts and complex geometries with:

- Excellent surface finish

- 96 to 99 percent density

- Mechanical properties equal to wrought steel

Below are the Phillips Medisize current material offerings. Other materials are commercially available or can be developed.

Stainless Steel

- 17-4

- 316

- 420

Low Alloy Steels

- FN02

- FN0205

- FN08

- 4620

- 4140

- 8620

- 8740

Soft Magnetics

- FeSi3

- FN50

Comprehensive Collaboration

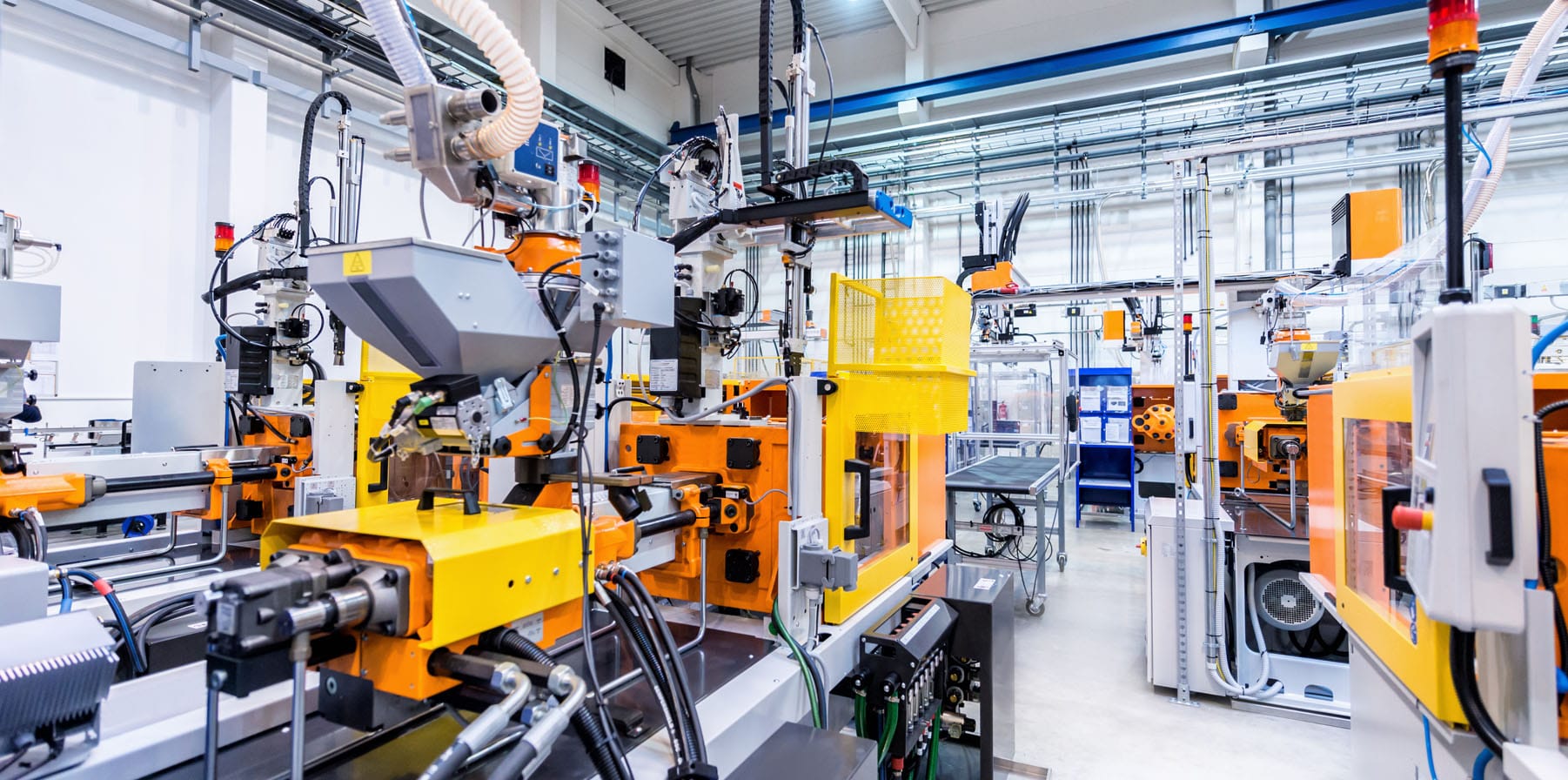

Phillips Medisize provides integrated in-house capabilities, state-of-the-art facilities and consistent communication to optimize process efficiency, control costs, tighten production timelines and reduce risk from start to finish. We help you manufacture customized metal components with 60 years of trusted expertise, including:

- Pre-award design assistance and comprehensive design for manufacturability (DfM) review upon project award

- Optimization of critical design factors prior to mold design

Featured Resources