Successfully Helping Consumer Brands One Product at a Time

Serving OEMs in virtually every market since 1964, Phillips Medisize has established itself as one of the premier sources for the designing and manufacturing of custom plastic and metal injection molded components. Our state-of-the-art manufacturing capabilities, knowledge and experience have built our reputation as a one-stop shop to design and develop some of the best-known home appliances.

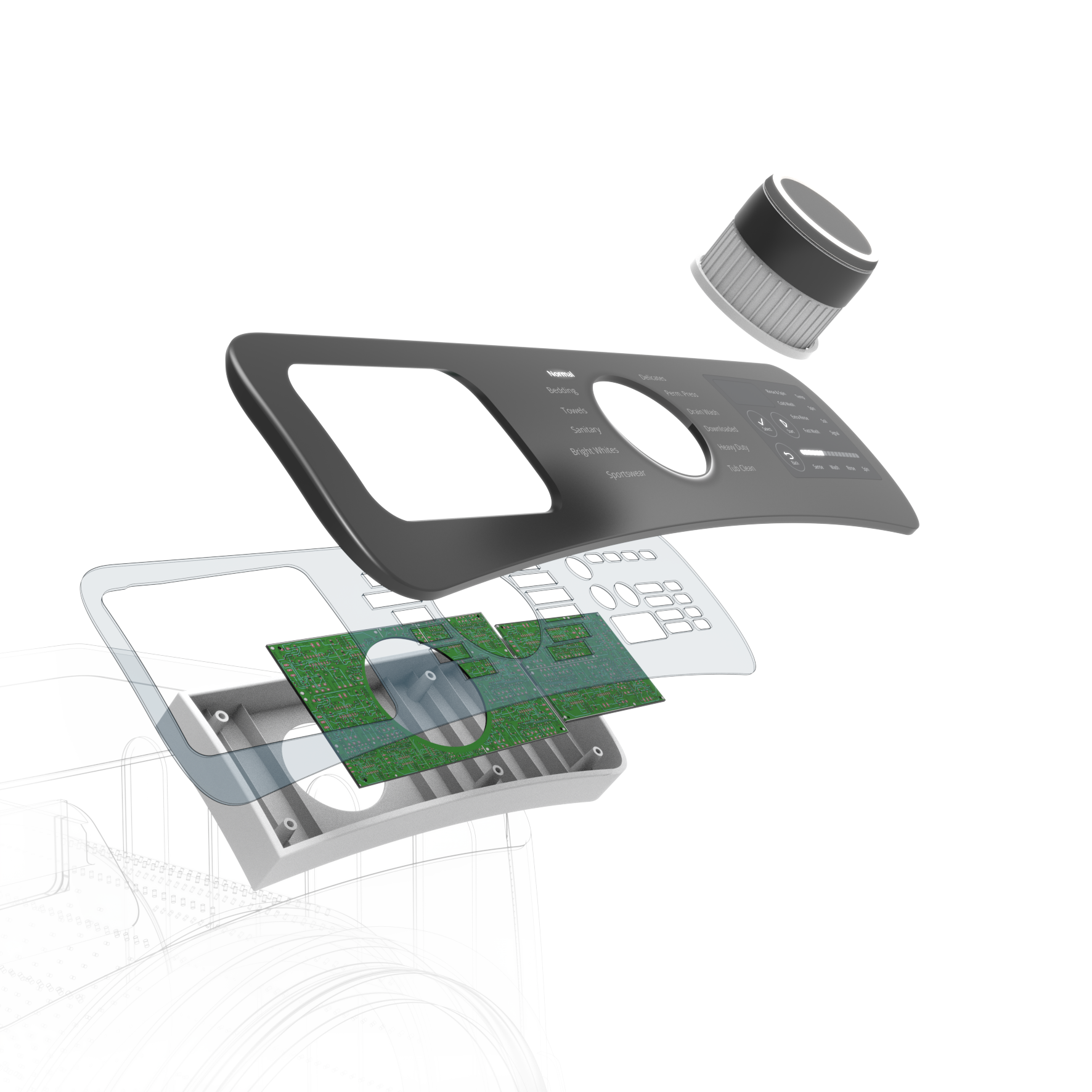

Consumer Product Design

Phillips Medisize’s expertise in developing consumer products such as home appliances makes us an industrial design and engineering resource of choice for the most respected OEMs in the marketplace. Utilizing a design for manufacturing approach, we develop concepts from the drawing board to packaged products for the consumer products industry.

- Accelerate time to market and launch with an optimized cost structure

- Comprehensive design strategy and feasibility testing

- Ability to leverage Molex electronics expertise and integration

Consumer Product Manufacturing

Our state-of-the-art consumer product manufacturing capabilities, combined with extensive knowledge and experience in material selection, have set the bar for consumer products with optimal performance, size and aesthetics. With resident experts in traditional plastic injection molding and multi-shot, in-mold labeling and design, liquid silicone rubber, metal, magnesium and decorating, Phillips Medisize is a global leader in the design and development of consumer products.

- Proven mastery in injection molding, decoration and subassembly integration with the ability to scale production and manufacture at high volume

- 145,000+ square feet of dedicated production space

- Automation capabilities to streamline component manufacturing

Consumer Program Management

Phillips Medisize has a proven history of handling customers’ programs with the dedication, pace, quality and standards that meet our customer needs.

Unparalleled Quality and Execution

For over 60 years, we’ve made quality the foundation of product realization. With robust Quality Management Systems and stringent global processes, we deliver world-class consumer products that realize exceptional outcomes.

- Standardized global design and program management processes, tools and software platform

- Robust program management processes designed to control the most complex, multisite programs

- ISO 9000 or IATF 16949 to ensure top-tier quality based on product customer needs

Appliance Integration Services

- Integrated production and assembly

- Worldwide supply chain solutions

- Diverse component offerings

- Cost-effective value engineering

- Dedicated account manager for streamlined communication

- Ongoing exploration and development of new technologies

- Comprehensive project management from discovery to delivery

- Continuous quality improvements and enhancements

- Comprehensive quality certified services

Featured Resources