Decades of Proprietary Advanced Injection Molding Capabilities

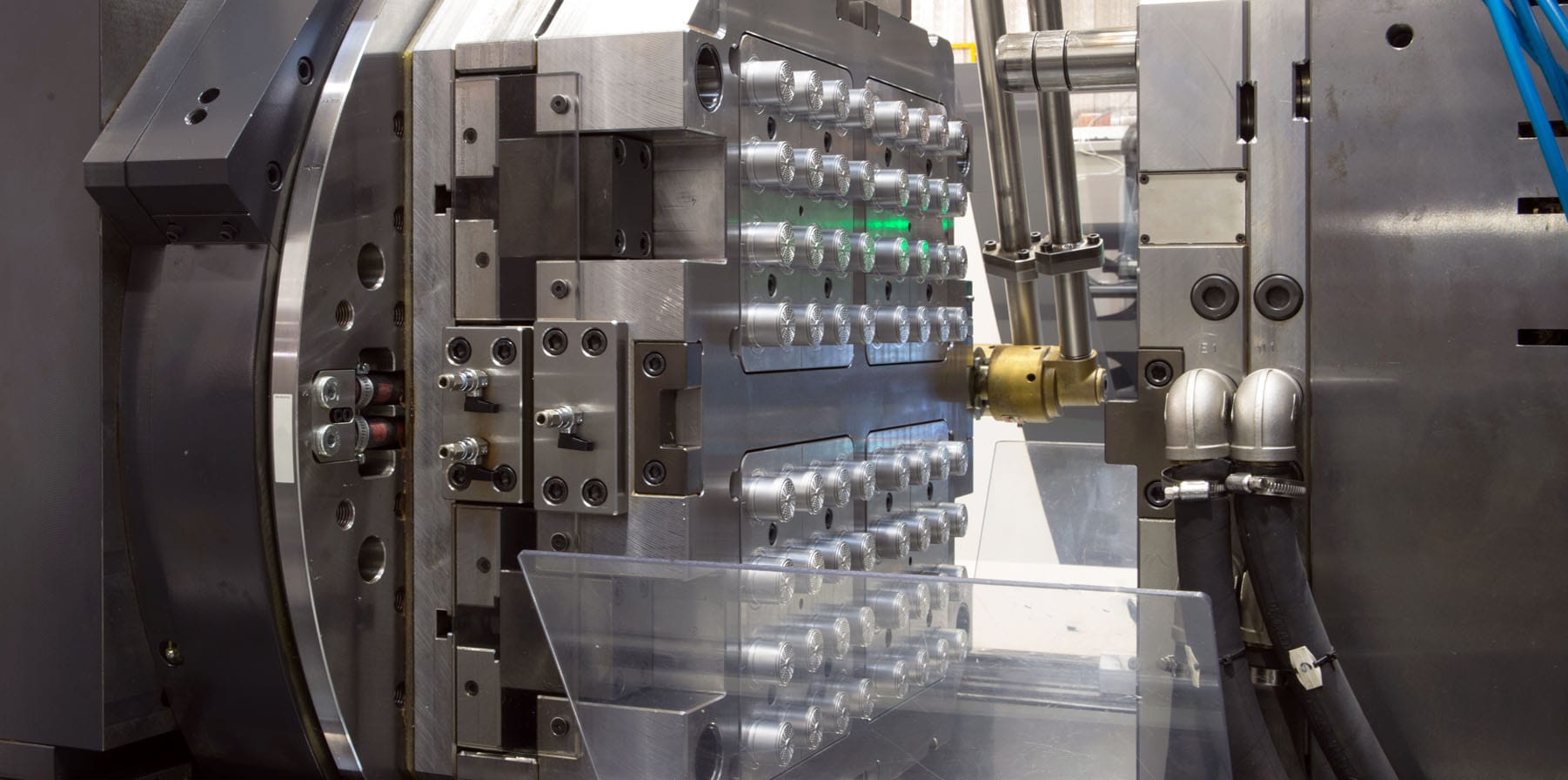

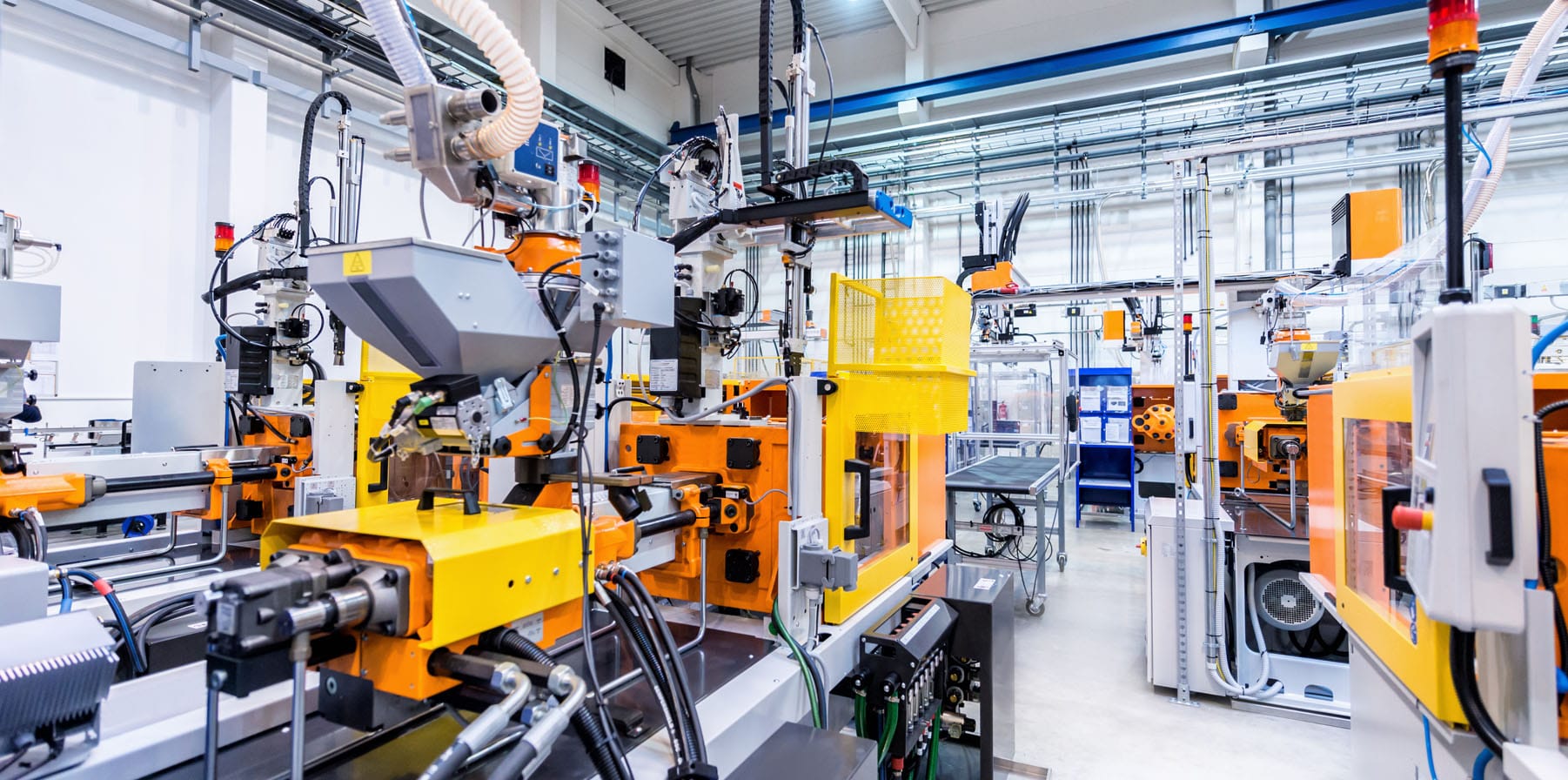

For the past 60 years, plastic injection molding has been central to our capabilities. Phillips Medisize focuses on working with the customer to understand and solve their needs and challenges and provide a comprehensive solution. This collaboration begins with part design review and then drives into design of the injection mold tooling and manufacturing process to meet the customer’s requirements economically and efficiently.

Phillips Medisize has standardized engineering, equipment and tooling approaches, allowing for scalable, global manufacturing and the flexibility to move production across geographies efficiently. We leverage the latest equipment, software and other resources to deliver outputs and production times that outpace industry norms. We also invest significantly in training our technical staff to ensure they are highly skilled in scientific injection molding processes.

We offer:

From discovery to delivery with our customers, we achieve our vision by:

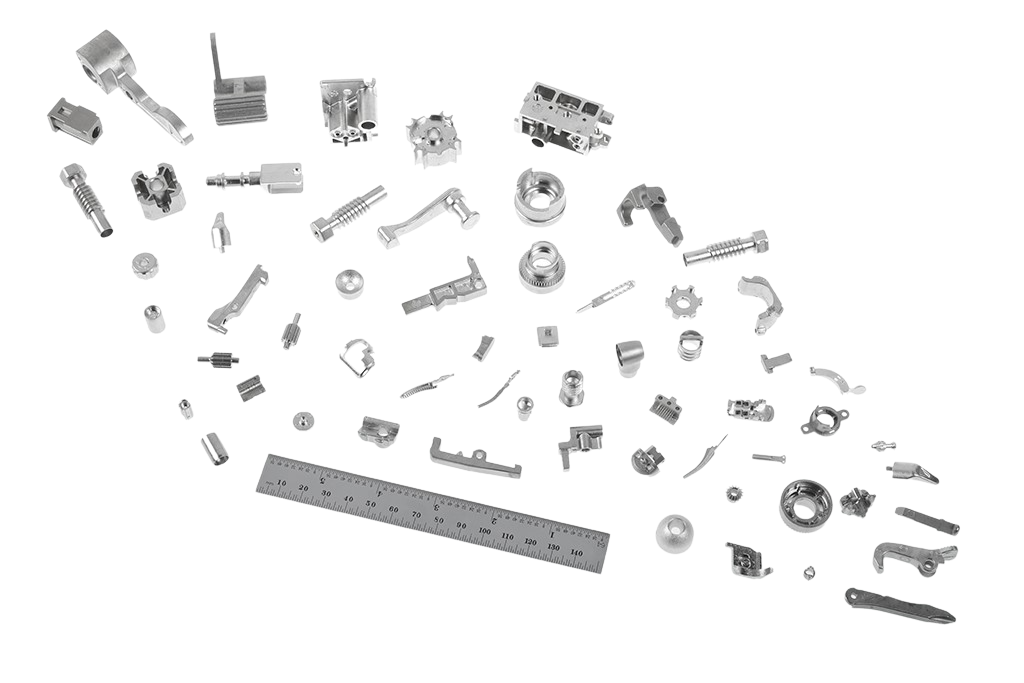

- Advanced plastic injection molding

- High-speed, high-cavitation injection molding

- Integration and assembly of metal sharps and electromechanical components

- Reel-to-reel insert molding

- Metal injection molding

- Magnesium molding

- Two-shot molding

- Liquid silicone rubber molding

- In-house tool design and build capabilities

Featured Resources