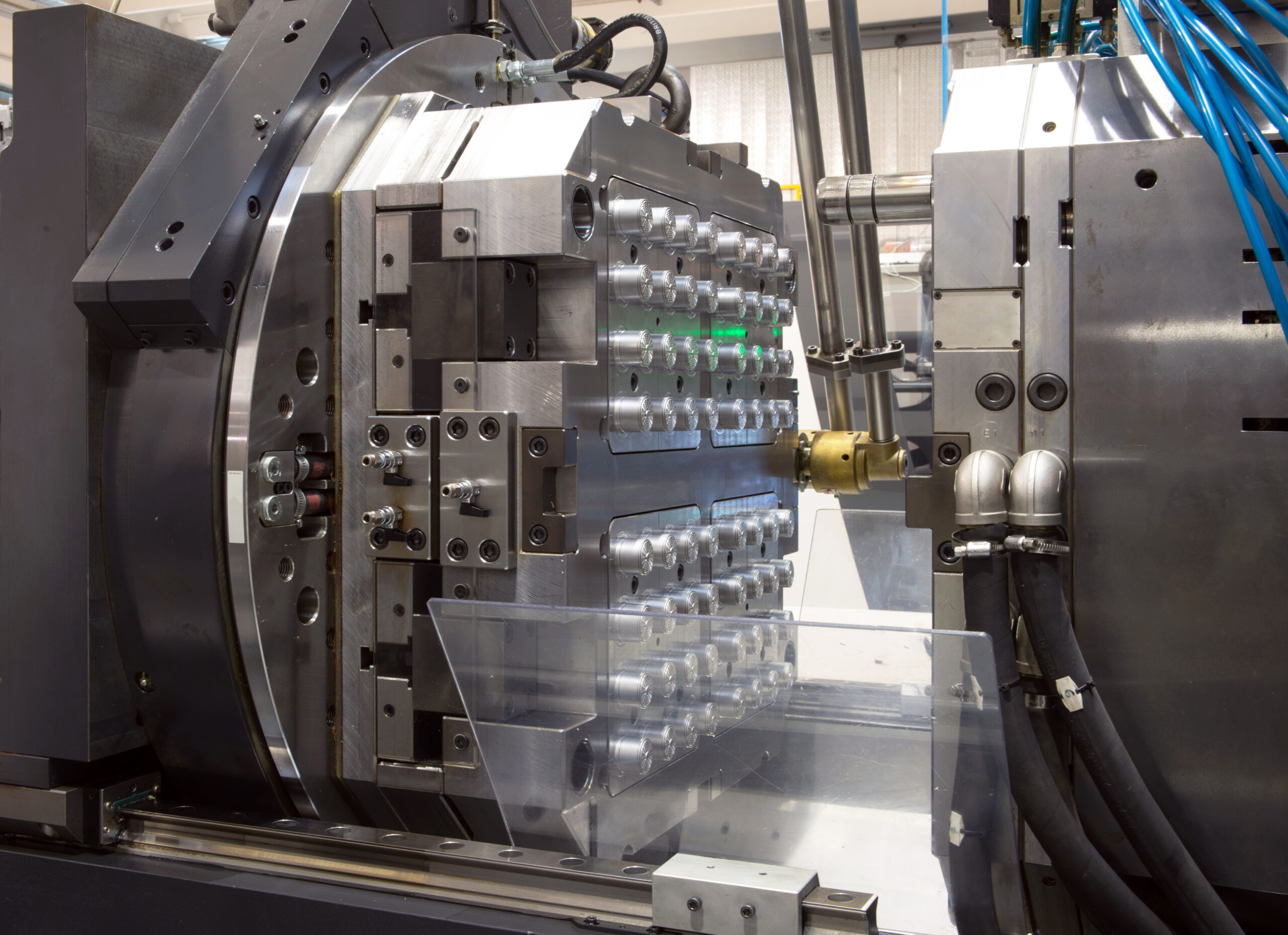

Create Precision Magnesium Parts with Magnesium Injection Molding

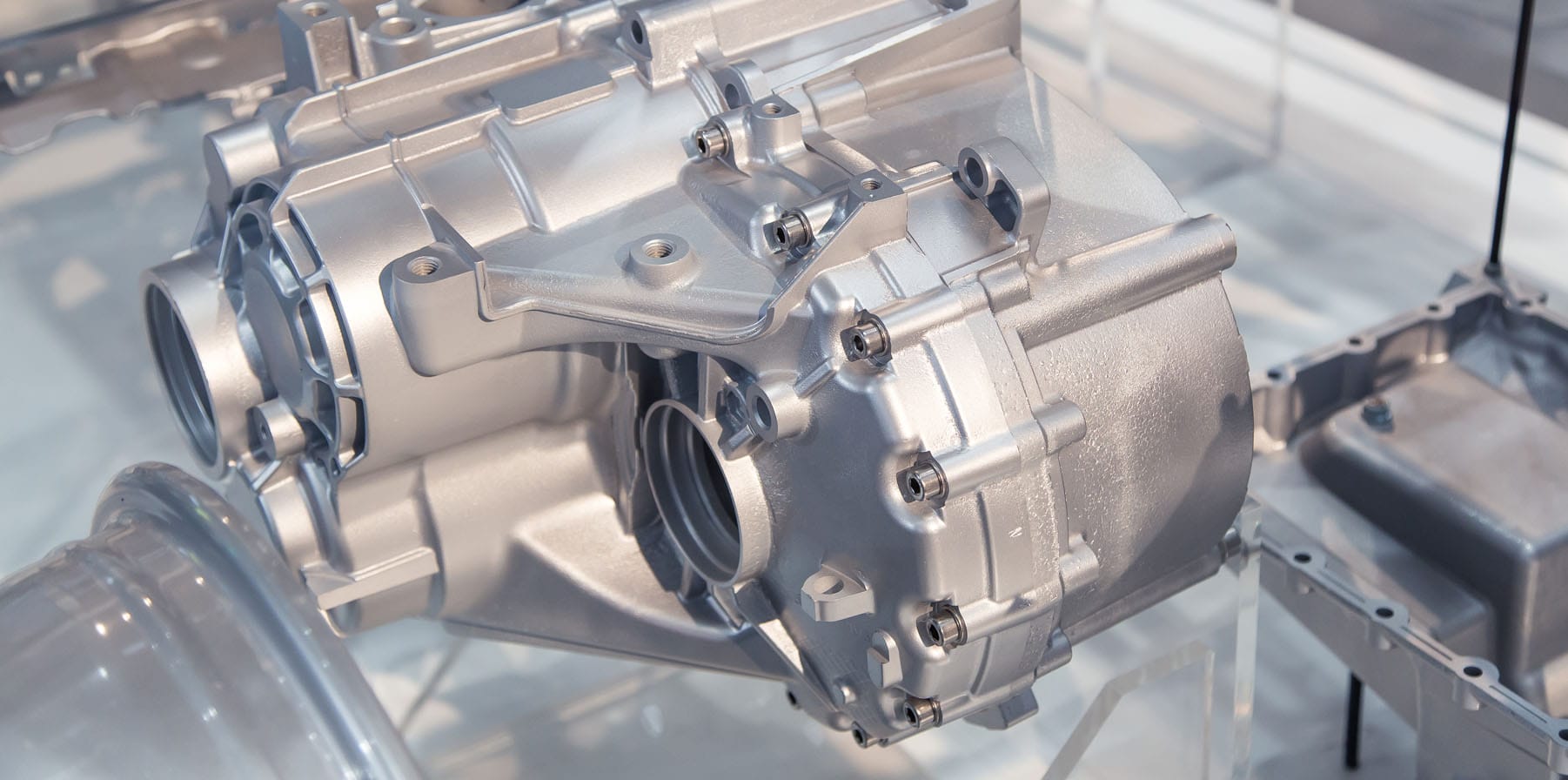

Magnesium injection molding (MAG), or thixomolding, is a single-step process where magnesium alloy chips are heated, processed into a semi-solid state and injected into a mold. This versatile technique produces complex parts and is increasingly favored in industries such as medical, electronics, automotive, defense, consumer products, sports equipment and handheld devices.

Superior Results

Phillips Medisize provides expert support with specialized injection molding techniques such as MAG, which accommodates large production volumes and minimizes secondary operations such as machining. Molded parts can then be conversion-coated and painted to meet your finished requirements. MAG allows you to cost-effectively manufacture customized components and complex geometries with:

- High strength-to-weight ratio

- 75 percent lighter than steel

- 33 percent lighter than aluminum

- Strength and stiffness two times greater than 30% glass-filled plastics

- Good heat transfer characteristics (less than Al but better than plastics)

- Inherent EMI/RFI properties

- Non-magnetic properties

- 100 percent recyclable

- Excellent damping capacity

- Corrosion resistance with conversion coatings

- Easy to machine

Comprehensive Capabilities

Using design for manufacturing (DfM) best practices, we provide gate and runner development as well as moldflow analysis to optimize the quality of your final part design. Transition seamlessly from concept through production with clear communication and step-by-step support. Our quality-focused magnesium injection molding capabilities include:

- Design assistance prior to project award

- Complete DfM review upon project award

- Detailed customer report generation

- Gating development, venting development and moldflow analysis upon design finalization

- Optimization of critical design factors prior to mold design

Featured Resources