Computed Tomography (CT) and metrology

In today’s highly regulated and innovation-driven industries, especially medical device manufacturing, precision and quality are paramount. Metrology ensures that every product meets stringent regulatory standards, enhances reliability and reduces costly rework. Complementing this, our in-house CT scanning technology provides non-destructive, high-resolution 3D imaging and functional testing, enabling faster development cycles and comprehensive quality assurance. Phillips Medisize leverages these advanced techniques to provide tailored, reliable solutions that help drive innovation and deliver on customer expectations.

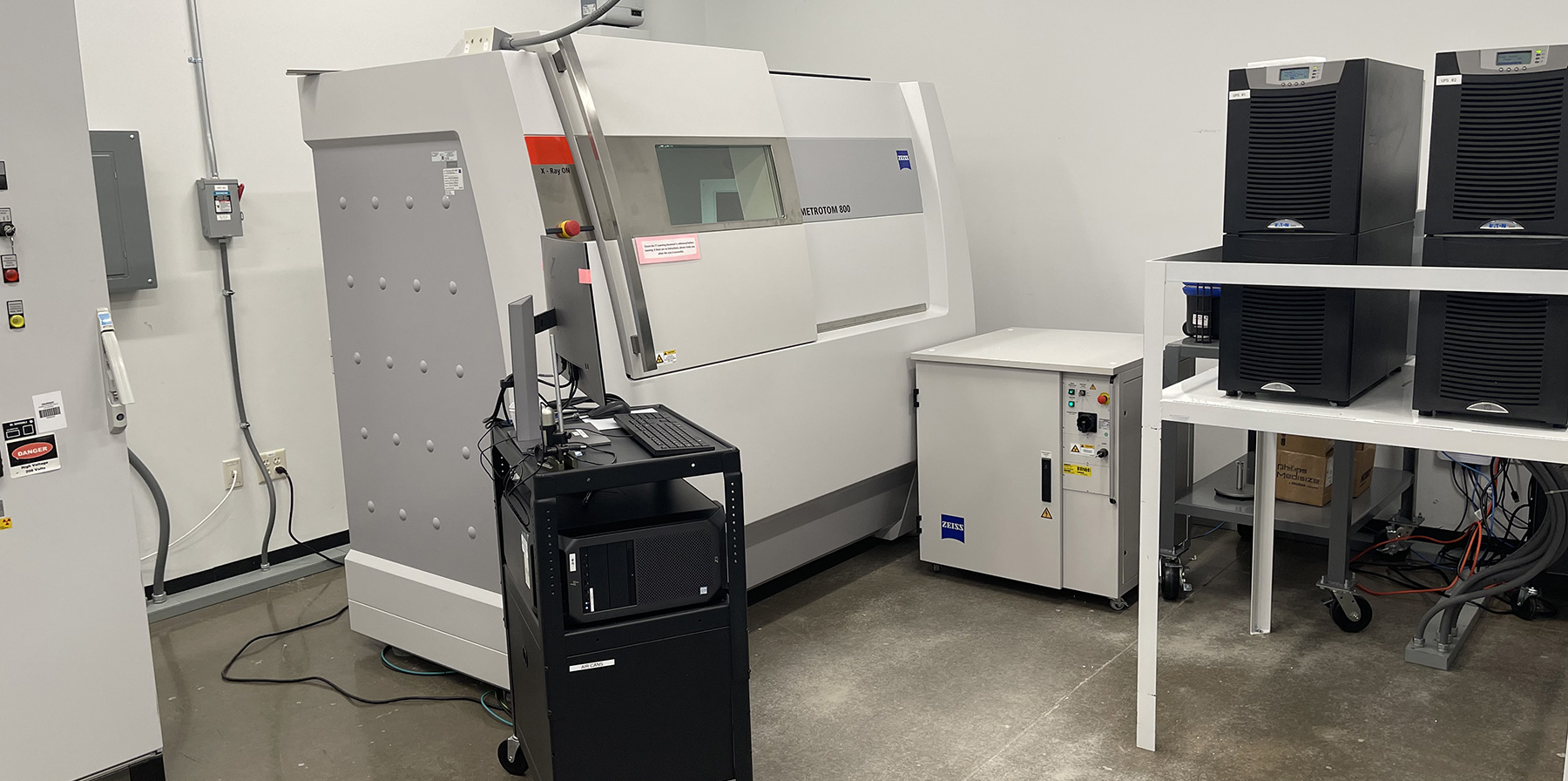

Computed Tomography (CT)

By using CT scanners, Phillips Medisize can maintain high standards of precision and reliability, essential to producing medical devices and other critical components.

Phillips Medisize is one of the few CDMO organizations with in-house CT scanning capabilities. Our state-of-the-art tool allows for:

- Accurate, repeatable data for research and development across various segments, such as medtech, pharma and automotive

- Real-time data, which is crucial for R&D and provides precise, first article inspections

- Functional testing, with the ability to run multiple cycles on fully assembled parts to troubleshoot issues and mitigate risks

Benefits of CT For Our Customers

With Phillips Medisize CT capabilities, customers can benefit from:

- Quicker production timelines

- Enhanced measurement capabilities, including non-destructive testing, high-resolution 3D imaging, material analysis, product development, assembly verification, failure analysis, CAD comparisons and complex geometry inspection

- More innovative research and development initiatives

- Helps meet customer requirements for certain applications

Importance of Metrology

Metrology plays a crucial role in ensuring the accuracy and quality of products, and is important for:

- Overall customer satisfaction, helps deliver high-quality products that meet customer expectations

- Regulatory compliance, helping products meet global standards

- Reliability and safety of devices

- Cost efficiency through the reduction of waste and rework

- Innovation through gathering the necessary data to explore new designs and materials

Differentiated Metrology Capabilities

Phillips Medisize’s capabilities can offer significant benefits to customers by delivering high-quality, reliable products that adhere to their exact specifications and regulatory requirements. We set ourselves apart through:

- Utilizing advanced technology for precise measurements

- Employing skilled professionals adept in measurement techniques, who provide tailored solutions to complex challenges

- Providing customized services to cater specific customer needs

- Integrating metrology throughout the product development life cycle, to speed up time to market

- Detecting issues early, helping to reduce the risk of defects and ensuring consistent product quality

Featured Resources